Tel: +86-13777263762

Email: [email protected]

Tel: +86-13777263762

Email: [email protected]

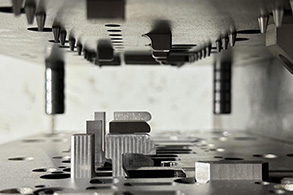

718 Steel is a kind of chromium-nickel-molybdenum alloy die steel, with a variety of unique properties and advantages. Its main features include: Pre-hardening treatment.718 steel has been hardened and tempered before leaving the factory, which can not only avoid the deformation risk of quenching and heat treatment, but also can shorten the mold production cycle and reduce the mold cost.

Good processing performance. It has high quenability, good electrical machining performance and leather processing performance, easy to cut, forging and welding, suitable for making a variety of complex molds.

Excellent mechanical properties.718 steel has excellent high temperature strength and heat resistance, can maintain high strength and hardness at high temperature; has excellent corrosion resistance, can resist acid, alkali, salt and other media erosion; at high temperature can form dense oxide film, effectively prevent oxidation reaction.

Good surface treatment performance.718 steel can be nitride and surface hardening treatment to improve the surface hardness and wear resistance of the die Excellent burnishability and photoetching performance. Prehard steel can be used for the die chamber without quenching, the flange can be flame hardened, and the hardness can be increased to more than 52 HRC and above 23.

High purity and uniformity. It ensures the consistency and reliability of the steel, and improves the accuracy and stability of the mold 35. In conclusion, 718 steel is a mold steel with excellent comprehensive performance, suitable for making high precision and long life molds and tools.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. All Rights Reserved - Privacy policy