Tel: +8613777263762

Email: [email protected]

Tel: +8613777263762

Email: [email protected]

A Journey Through The World Of Progressive Stamping In Production

Do you ever even ponder the means that go into turning raw metal into products? A very interesting one is the procedure named as progressive stamping. This advanced method of manufacturing plays a significant role especially in the manufacturing world as it helps to produce parts for diverse machines and tools. In this post, we delve deeper into the world of progressive stamping and how it helps build high-quality products with adherence to industry standards.

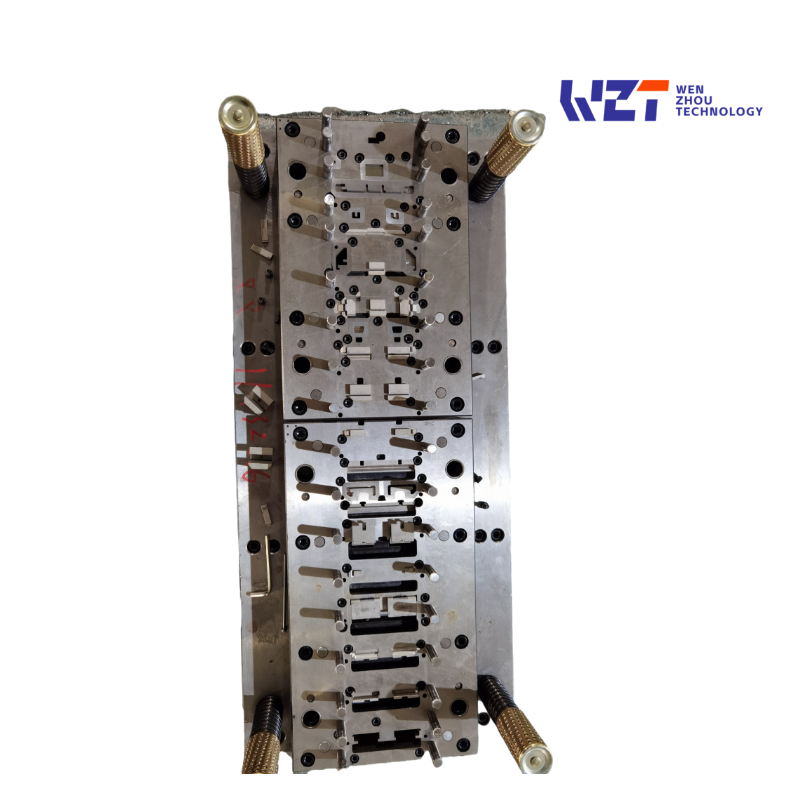

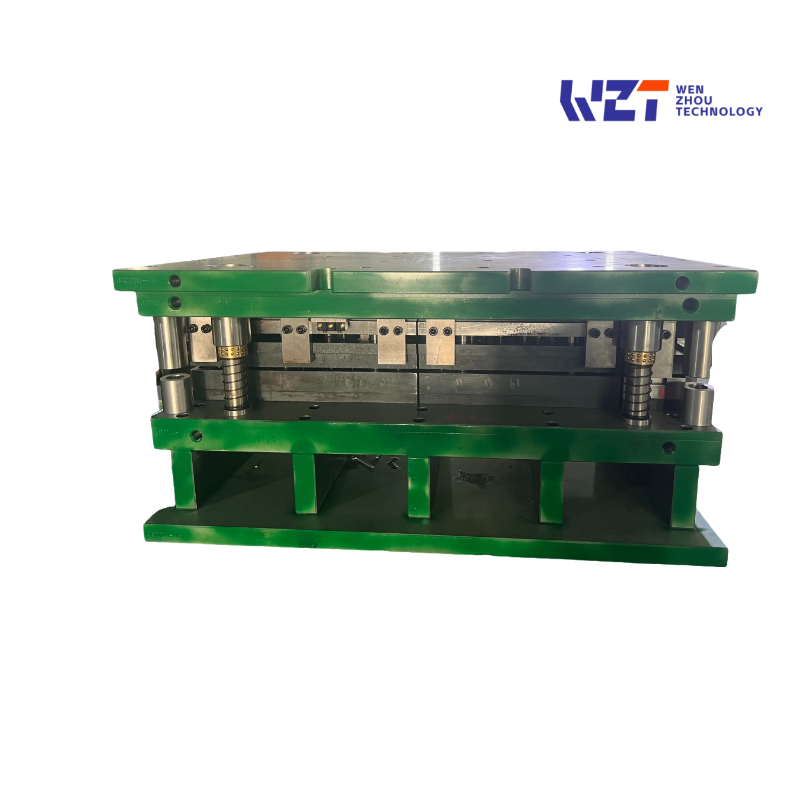

One of the most efficient ways to produce many metal components at once is by using progressive stamping technology. This involves pass the metal through a set of specialized dies in machine centers. This is carried out in several dies, each of which will shape the metal a little bit more until you get what you want. This way, it is much faster than manufacturing each part separately and sheets ensure metal shaping accurately.

Progressive stamping has a unique advantage in that it helps streamline the manufacturing process. This way all can easily happen at one place and you save yourself from using various machine to perform different processes. As a result, production times are shortened and total number of finished goods is amplified.

Throughout the years, thanks to advancements in manufacturing and its processes we can see how much of a leap Progressive stamping managed over metal shaping. Traditionally, the methods for shaping metal were laborious and involved cutting it with a saw or pounding into shape. These methods were slow and prone to produce repeatable, but often-freely formed products.

On the flip side, progressive stamping methods offer greater accuracy and control of metal forming. As these processes are automated in nature, it guarantees the complete monitoring of accuracy and speed. This makes the products uniform in size and shape which greatly helps with assembly and use.

This intent to produce the best products possible continues today, thanks in large part due to progressive stamping. This metal shaping process allows manufacturers to make products that are consistent in size and shape. This standardisation improves the performance of products and minimises defects.

Standardized products help smooth the process of assembly and ensure manufacturers can use fewer parts, which is a win-win as it also lowers manufacturing time. This results in cost saving for companies and improved profitability.

Advanced Progressive Stamping Methods Change the Game for Production Processes

Manufacturing is always changing, so progressive stamping represents one of the newest and most advanced methods out there. This technique enables fast and accurate production of many components. However, it is possible to manipulate computers that monitor the process quite closely and therefore ensure all parts are of a uniform size.

Progressive stamping has made a giant impact on the manufacturing process with faster and more economical outputs. Companies can now mass-produce products quickly, shortening the length of time between conception and realization on to store shelves. This has advantages for producers and customers alike.

Making complex metal parts has always proved difficult for manufacturers. Fast forward to today, and progressive stamping has revolutionized the way complex shapes can be made. Now, this process that was earlier limited into bending and shaping soft metals is able to bend and shape hard metal like rebar.

This innovation in manufacturing allows manufacturers to create new and complex parts that differentiates their product in the market. In addition to that, you would be having more options for products,since they can easily cater your customization needs.

To sum it up, progressive stamping is the backbone of manufacturing. It increases productivity and accuracy, drives forward manufacturing processes, improves product quality and consistency, changes industry production methods entirely, and provides innovative ways to manufacture complex parts. Unlike progressive stamping itself, however, this trend is only going to get more effective as technology advances. The future of metal shaping is endless!