Hello, everyone. In todays post, we are going to talking about very something interesting and sexy: STAMPING MOLDS.. A stamping mold is a special device that aids in producing the same part repeatedly under pressure and heat. This allows factories to produce a large number of identical pieces in little time. Molds in this way for embossing are utilized by organizations everywhere throughout the planet, one such case is France. These companies can be anything from car factories producing automobile parts to airplane manufacturers who produce parts for planes. While we investigate into stamping molds and how are they used in France.

What Are Stamping Molds?

One of the important roles played by stamping molds in France is to produce products from a wide range industries. This helps in the creation of many components such as metal sheets (flat piece formed into 3D) and plastic pieces which can further be used for different articles. Quality: The FrenchThe French have a reputation for superb craftsmanship. They treat their work with care and take enormous pride in what they do. Stamping molds pay a lot of attention to details, which can help them manufacture durable high-quality products.

Stamping Molds In FranceSegments For Stamping Moulds

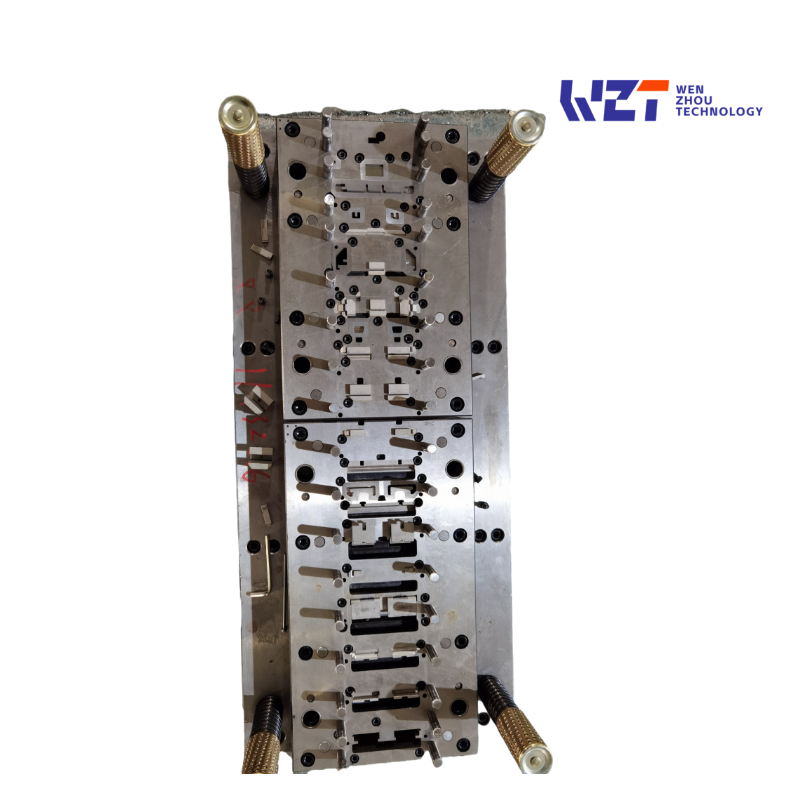

There are some varieties of stamping molds by WenZhou that use in France and all types have their own advantages planetary system. In this article, we will discuss some of the types in more detail:

Progressive Dies: these are very intricate molds for parts that require several steps to the end. They are a template to move the component through different stations that perform individual functions or operations in order for the part to be finished.

Transfer dies: They are somewhat similar to progressive dies, but still function differently. Transfer dies allow for the part to be moved from one station to another during manufacture; with a person doing so, allowing more control.

One stage glasses: These are single process molds allow regarding one functioning to be accomplished. They are commonly used when a factory must produce many copies of the same part, specifically in high-volume production situations.

Materials for Stamp Molds in France

These are used to produce the stamping molds and can withstand high-precision working environments of steel, aluminum or plastic. France uses steel as a material for Stamping material molds, and is the most common. It is very strong and durable, can be reused over time for Manufacturing. Aluminium and plastic are both also options in some cases, either when you need something lighter or if the design calls for it.

As Equipment in Stamping Molds Is to Be Used at France

In France, stamping molds are widely used in various industries such as automotive and aerospace. The following are some examples of how to use them in these critical sectors:

Automotive - In the automotive sector, Stamping Products can help fabricate key parts for automobiles and trucks. The activities in this step include, but are not limited to body panels (exterior covers outside the car), frames (the core structure and support).

Aerospace- Stamping molds create different airplane parts in aerospace. Wing forms, vital wing components need to flight; main body of the aircraft in tow frames.

Medical: Stamping molds have a significant impact on the medical field as well. The material is integral to the production fast-turn, highly engineered medical devices such as pacemaker components (e. g. lead bodies) that regulate heart control and surgical screws for bone fixation interventions during surgery;

Electronics: Finally, punches find an application in producing parts for electronic devices. The accessories are from making phone cases that protect our vital smartphones to circuit boards, being the heart and soul of most electronic devices.

Selective Choosing of Stamping Mould and Maintenance

In a workshop, the mold to stamp should be selected in order for producing of high quality parts. Tips in choosing and managing stamping molds

Choose the stamping mold correctly to choose the correct type for your needs. As we reviewed each stamping mold, they all have their capabilities and limitations with the type of design so best deciding for your needs will produce optimal results.

Wash it off: Clean your stamping mold with water after use This will help keep it in proper operating order and prevent any leftover material from contaminating future parts. Also be sure to inspect the mold often for any damage.

My advice is to buy the best quality molds you can: good stamping dies are not cheap, but spending those first couple years trying to Appease The Sparta Gods and grinding subpar die steel against washers will surely cost your organization far more in time (and therefore money) than a 10-30% premium on a finished piece. Higher quality molds are designed to have a longer life than lower quality parts and therefore will last much longer producing better, more reliable pieces.

To wrap up, French stamping molds are essentials so as to ensure the manufacturing of impeccable. They produce many components for cars, planes and various products prevalent in people's daily lives. Workshops in France are able to deliver top-grade parts, which largely satisfy the performance requirements of their clients and provide a valuable economic benefit for local industrial sectors through selecting an appropriate stamping mold with high quality tool maintenance.

EN

EN