How to Stretch the Life of Your Stamping Molds

Molds are crucial in the manufacturing of products such as toys, containers and car parts that we use on a daily basis. Making sure these molds are well cared for is imperative to ensure that they last a long time. With that in mind, let us explore some expert tips to maintain and extend the life of your stamping molds for maximum efficiency.

The Significance of Stamping Molds

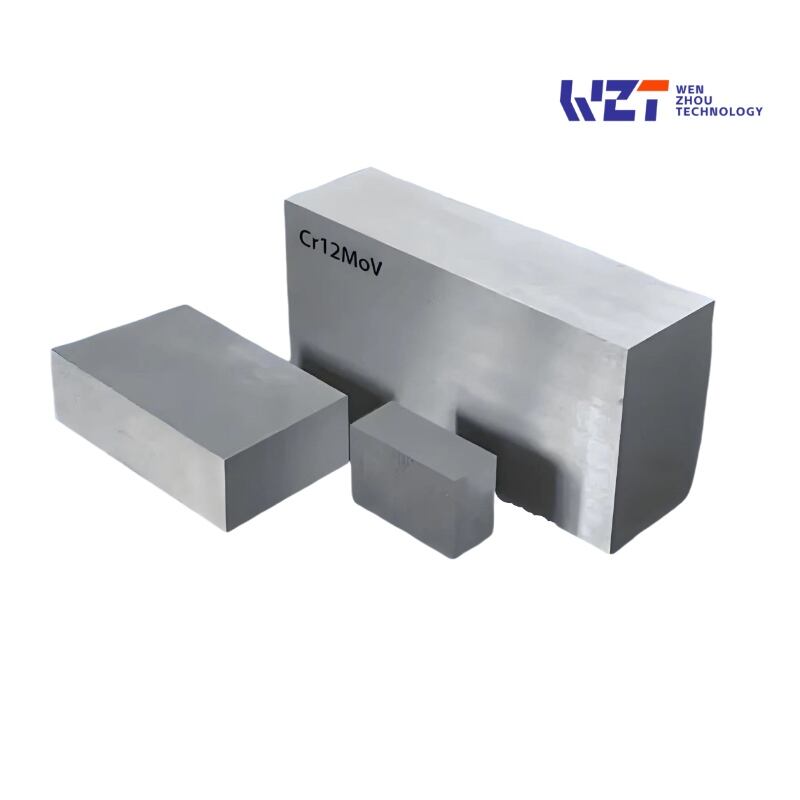

A stamping mold is generally made of metal, and it adopts the form or profile in shape of the workpiece. This molten material is poured inside the mold and on cooling down, form a solid object of required shape. But the material loses temperature through splitting, causing wear to the mold leading it being ineffective after extensive use.

Stamping Mold Maintenance Tips

Deep Clean: You should clean the mold very seriously after each use to remove all stuck materials from its surface by using a soft cloth or brush. Make sure not to use abrasive or pointed tools, as these could scratch and ruin the mold.

Proper oil Lubrication:Use a stamping-mold specific lubricant to decrease friction and wear from continued use Don't forget to grease mould before & after each application.

Just so that we can get the mold and store it properly when not in use keep them at a cool dry place away from moisture or other chemicals that might harm it. As an additional protection, you might coat your mold by a protective layer which is going to protect against oxidation.

Increasing the Life of Your Molds.

Stamps you care for properly will last longer than poorly cared-for stamps; and vice versa. Molds Materials - Aluminium molds are cost-effective; they also tend to wear out fast because most of the time, inexpensive metals get used in making them. Choosing molds made from reinforced, heat resistant and corrosion repelling materials like strong metals will greatly increase the longevity of these moulds.

Additional Mold Life Improvements

Proper Pressure Implementation: When applying the mould, make sure you don't put too much pressure as this will wear it down faster and prevent it resisting in longer run.

Temperature: Correct temperature of molding material in pour stream. Overheating the mold does damage it and restrict its duration of operation.

Mold Saving and Productivity Improvement Tricks That Have Been Used for Generations

Use these expert tips and tricks to effectively boost productivity and increase service life of your stamping molds in order to get better results. Proper mold care and maintenance are essential to keeping your molds in top condition, giving you good products throughout their life.

To summarize, stamping moulds not only are widely used equipment responsible for the daily necessities yeezy clearance of our life. Using the advice provided in this article will help you efficiently protect and elongate your stamping mold tools which means higher production rates as well an augmented material than ever RuntimeObject.

EN

EN