Tel: +86-13777263762

Email: [email protected]

Tel: +86-13777263762

Email: [email protected]

P20 steel is a kind of hot-working die steel with the following characteristics:

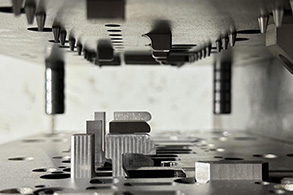

Pre-hard state: P20 steel with pre-hardness range of HRC 25-29, providing uniform hardness and organization. This pre-hard state allows the steel to be used directly for mold processing without additional heat treatment, thus shortening the construction period. Processing performance: P20 steel has good cutting performance, polishing performance and welding repair performance, suitable for polishing and corrosion processing plastic mold processing. After forging and rolling processing, the tissue is dense and can pass 100% ultrasonic test, without stoma or needle hole defects.

Chemical composition: The chemical composition of P20 steel includes 0.38% carbon, 1.30% manganese, 1.85% chromium, 0.40% molybdenum and 0.008% sulfur, which give P20 steel good hardness and plasticity.

Application areas: P20 steel is widely used in the production of plastic mold, die frame, die casting low melting point metal die materials, as well as the main components of various heavy load molds. In addition, it is also suitable for making car bumper molds or other parts on the structure.

Copyright © Ningbo Wenzhou Technology Co.,Ltd. All Rights Reserved - Privacy policy